Recycle & Reuse, Reduce costs than Zero Liquid Discharge

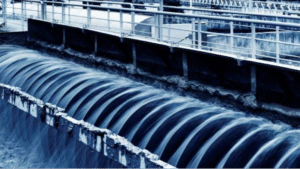

Industrial manufacturers are busy seeking the best possible solutions for wastewater treatment which would act as the most powerful weapon at their disposal in Zero Liquid Discharge or ZLD. There have been application of a lot of advanced methods like reverse osmosis, evaporation which results in crystallization. These procedures purifies and recycles all wastewater absolutely leaving zero liquid discharge at the conclusion of the treatment process.

Many manufacturers really don’t realize that the ZLD is a much more expensive factor when you compare it with the practical aspects of water recovery or reuse, which can be much effective. ZLD can be the most sensible solution for organizations which really do not have a discharge point which is much near to their plant. This can lead to significant treatment of source water which should be purchased. ZLD would have a 100 % of water recovery, which would have no or minimal waste haul off. The ZLD treatment is not required or can be really not affordable for many organizations where practical water reusing results in 70 to 85 per cent of water recovery. There will be discharge for which a permit is needed but the method recovers easy water with absolutely low Total Dissolved Solid wastage.Each industrial manufacturer can decide the method of wastewater treatment which can be optimal in solutions. Its important to consult an expert like GME before making any kind of investment in a strategy which is affordable with a high value.

More Blogs

Is it safe to use Water after Sewage treatment

Is it safe to use Water after Sewage treatment...

How does a Waste Water Treatment Plant Come

How does a Waste Water Treatment Plant Come Into...

Wastewater Treatment Plant for Hospitals

Wastewater Treatment Plant for Hospitals: Keeping Environmental Sustainability at...